In accordance with local and state regulations, all biohazardous waste must be biologically-inactivated before it is disposed of as regular trash. This can only be achieved if the waste is exposed to the right temperature for the right amount of time. Optimally, the waste should be exposed to: 121 degrees C, at a pressure of 15 PSIG for at least 20 minutes.

Autoclave gauges are not always accurate, and autoclave tape only indicates the presence of hot steam. Therefore, the autoclave must be validated on a regular basis with a biological indicator ampoule or chemical integrator strip that clearly demonstrates that the appropriate conditions were achieved for sterilization.

Responsibility for validating autoclave performance lies with those who use the autoclave for treating biohazardous waste. It is strongly recommended that a designated individual be identified among the lab staff who will be responsible for the validation of the autoclave and the training of personnel who use this equipment.

UT Biosafety Recommended Practice for Autoclave Validation and Use

Each quarter all autoclaves used to treat biohazardous waste will be validated using 3M Comply Thermalog™ Steam Chemical Integrator strips, which will be provided by the Biosafety Office upon request (974-1938 or 974-9836). Chemical integrator strips test the time, temperature, and quality of steam exposure and are calibrated to mimic the results obtained using the traditional Bacillus stearothermophilus biological indicator tests (i.e., spore tests). However, chemical integrator strips give immediate results rather than requiring the 24-48 hour post-autoclave incubation period necessary for spore germination and growth. Based on prior parallel validation testing experiments, there is no difference between the chemical integrators and biological indicators. However, the Biosafety Office will perform spore tests along with the chemical integrators if validation problems/inconsistencies arise.

One misconception that often arises is that biological waste is inactivated as long as the autoclave chamber achieves the proper conditions. However, remember that autoclave performance is affected by load size (volume) and load contents. For example, 121 degrees C for 15 minutes may be adequate to sterilize 2 L of media but not 20 L of media. Thus, achieving proper chamber conditions does not always guarantee sterilization for the entire load. This is especially true for bagged biohazardous waste. Complete inactivation of bagged biowaste can be a challenge and often requires a few additional procedural precautions. The table below illustrates two common problems likely to negatively impact the complete inactivation of bagged biowaste and tips to remedy these problems.

| Problems | Solutions |

| Inadequate steam penetration and exposure | Biohazard bags are not usually steam permissive, so:

|

| Overstuffing the chamber | Bagged biowaste is often bulky or high volume, so:

|

To summarize the details specified above, the Biosafety Office has developed a standard protocol for the validation of autoclaves used to treat biohazardous waste. The autoclave validation procedure is outlined below:

Autoclave Validation Instructions

- Place a full, medium-sized biohazard bag (e.g. 25″ x 35″) into an

autoclavable secondary container. - Add 1 cup (~250ml) warm water to the bag. This is recommended for all bagged waste, but it is required if the contents are not likely to generate steam within the bag (e.g. bag contains mostly dry plastic disposables).

- Place a 3M Comply Thermalog™ Steam Chemical Integrator strip inside the bag near the center of the bagged contents. Make sure that there is a mechanism for retrieving the strip after the validation test. For example, affix a piece of twine to the strip and tape one end of the twine to the outside of the bag.

- Place bag into the autoclave, leaving the top of the bag open to facilitate adequate steam penetration into the bag. Make sure that the bag is opened widely at the top and that it is not bound, tied, twisted. Also, take care not to obstruct the opening of the bag by “cramming” the bag against the walls or ceiling of the autoclave chamber.

- Autoclave the biohazard bag for a minimum of 30 minutes at 250F/121C. 30 minutes is the recommended minimum, but sterilizations of >1 hour are not abnormal depending on the autoclave and load volume/contents.

- After cycle completion, note the status of the chemical integrator. A successful test is achieved only if the blue indicator line reaches any portion of the “Safe” window.

- Document the validation test. Documentation should include the following:

- Date and time of test

- Load contents

- Parameter setting for autoclave

- Type of test and results of test

- Name of person performing test

- Failed attempts and remedial actions as necessary

- If the validation was successful the biohazard bag may be tied up and

discarded into a non-see-through trash bag for final disposal. If the

validation was not successful, repeat the test and add 10 minutes to the

sterilization cycle. Integrator strips are single-use only. Use a new strip for each retest.

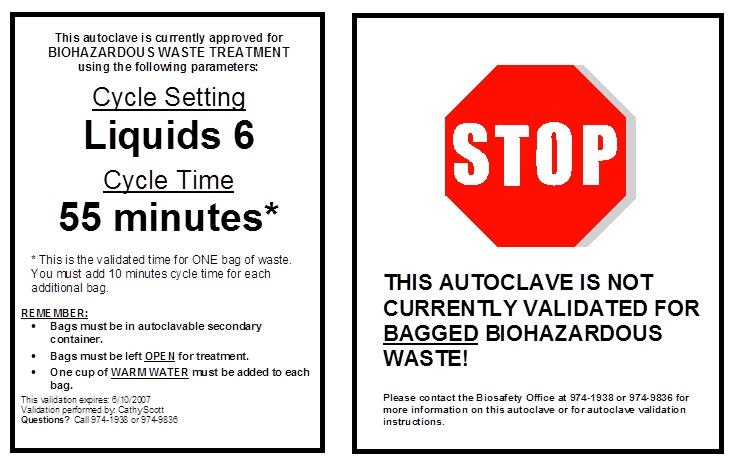

The autoclave settings that are validated as necessary to achieve effective sterilization of wastes should be communicated to the Biosafety Office so that a database of autoclave validation results can be maintained. Additionally, the Biosafety Office will generate a sign indicating the validated cycle and time settings to be printed and posted by the autoclave tester. Autoclaves that are not validated for biohazardous waste will also be posted accordingly. Examples of autoclave postings are provided below:

Because autoclaves present a number of hazards, only those personnel who have received on-site training by the lab’s designated trainer should operate an autoclave. A general procedure for autoclave treatment of solid biohazardous waste (non-sharps) is as follows:

Biohazardous Waste Treatment by Autoclave

- Use secondary containment (i.e. cart) for transporting waste bags to the autoclave for treatment to reduce the possibility of a spill during transport.

- Add one cup of water to each bag to facilitate air displacement and enhance steam generation.

- Leave bags open to facilitate steam penetration.

- Place bags in autoclavable secondary containment pan for autoclave treatment to reduce the possibility of a spill during treatment.

- Follow waste cycle parameters established for the autoclave to assure effective decontamination of waste.

- 6. Unload waste after cycle is complete and chamber pressure has returned to 0 PSIG. Do NOT override safety features to open the autoclave.

- Use autoclave gloves and appropriate eye protection to avoid injury from contact with hot surfaces or liquids when removing waste from autoclave.

- Tie or band the treated bags closed to reduce the possibility of a spill.

- Dipose waste in designated “autoclave treated waste” bins.

Do NOT autoclave wastes that are contaminated with hazardous chemicals!